Case studies

Kukule Ganga Power Station

Project Summary

|

Project Value: |

£170,000 |

|

Service: |

Repair & Refurbishment |

|

Duration: |

3 Months |

Background

Ceylon Electricity Board is the largest electricity company in Sri Lanka with a market share of nearly 100%. It controls all major functions of electricity generation, transmission, distribution and retailing in Sri Lanka.

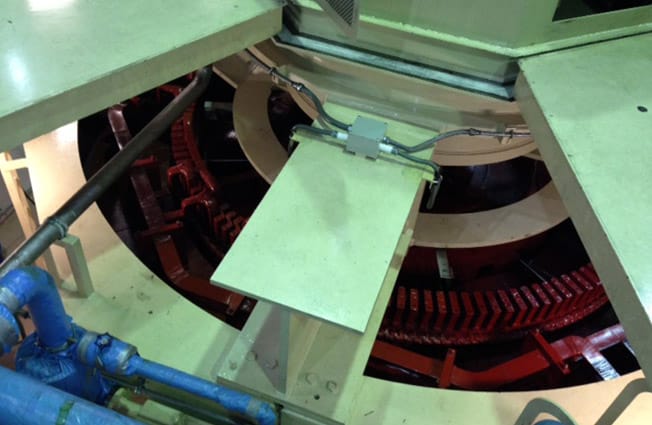

Kukule Ganga Hydro Power Station was commissioned in 2003 and generates an average of 317 GWh annually. The unit 2 generator suffered a failure following the detachment of a securing block from one of the rotor poles whilst the generator was in operation which resulted in damage to the lower end of the generator including:

- Impact damage to the stator core and stator bars

- Electrical damage (earth faults) to the core and stator bars

- Significant damage to the rotor damper winding

- Impact damage to the field winding on some of the poles.

The Project

Quartzelec were awarded the contract to supervise the generator repairs of a vertical synchronous 12 pole hydro generator, rated at 42000kVA, 13800V, 50Hz, 500rpm. This included removal of most of the top stator core and several bottom stator bars where the core was damaged.

The core was ground and etched in the damaged areas to remove shorts between the laminations. Once this was complete, the stator bottom bars were reinsulated and reassembled in the stator.

In terms of the spare top bars, the stations stock were used. However more top bars were required to complete the repair so Quartzelec shipped 30 bars to our state of the art coil shop in Rugby UK to strip and reinsulate the badly damaged bars. These repaired bars were subsequently rewound into the stator at site and the stators and windings thoroughly tested before reassembly of the rotor.

The main issue with the repairs apart from the technical complexity of the stator core and bar repairs was the time pressure to have this unit available for the next rainy season. From very close project management control and liaison with CEB technical officers, this was achieved satisfactorily to the grateful thanks of CEB management with the unit being returned to service in November 2013.

The core temperature in service is now satisfactory considering the repairs undertaken and the overall partial discharge level of the generator has lowered following the repairs to the stator bars.

CS17

Rue des Finettes 54

1920 Martigny

Switzerland